Complete medical collection kits, from custom design to result

Medical kitting is more than assembling a practical set of sampling materials. It’s a specialized process that demands precision, reliability and customisation. DaklaPack develops, assembles and distributes medical test kits for healthcare, the pharmaceutical industry, research institutions, commercial test providers and governments. From blood collection to swab testing: we create sampling kits that align seamlessly with your process and end user.

We combine years of experience in packaging innovation with up-to-date knowledge of logistics, regulations and medical research. The result is a full-service kitting solution that meets the highest standards for quality, safety and traceability.

What is medical kitting?

Kitting involves assembling complete medical test kits made up of multiple individual components. Think of tubes, swabs, clear instructions, return packaging, barcode labels and necessary consumables. Every element is tailored to the purpose, the testing method and the end user. Thanks to our modular approach, the kitting process can be fully adapted to your needs, from concept and sourcing to fulfillment and optional returns processing.

Who is our kitting service for?

Medical kitting is ideal for organizations involved in sample collection across a wide range of contexts, from prevention programmes to clinical research. Whether you're setting up a pilot or managing large-scale testing on a regular basis, having a reliable and flexible partner makes all the difference. With our experience in complex processes and streamlined logistics, we respond quickly and ensure consistent quality. Our kitting services are suitable for:

- Healthcare institutions and laboratories

- Government bodies and screening programs

- Employers and prevention initiatives

- CROs and research institutions

- Pharmaceutical companies

The kitting process in 6 steps

DaklaPack’s mission is to take the entire process off your hands, from developing new concepts and designing kits to shipping them out. Our experienced specialists take into account legal requirements, user-friendliness and efficiency during production.

Our kitting proposals are all-inclusive and cover the sourcing of components, kit assembly, IT integrations, warehousing and order processing. As a DaklaPack customer, you also get personal access to a clear and user-friendly portal for managing your inventory and orders. The kitting process can be divided into the following phases:

Six steps to your kit

- Phase 1: Thoughtful kit design

- Phase 2: Barcoding and traceability

- Phase 3: IT-platform integration

- Phase 4: Manufacturing and procurement

- Phase 5: Assembly and production

- Phase 6: Warehousing and order fulfillment

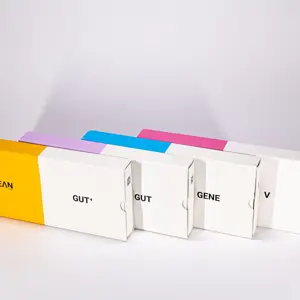

Specimen collection kits are about more than just convenience, it often is the only physical aspect of the product and service you are providing and therefore it is important to ensure your customized kits have the right look and feel for your brand.

The design has a great impact on how the kit is produced, assembled and processed, but also on customer experience and user-friendliness. Kit design should therefore not only focus on branding and usability, but also account for manufacturing efficiencies, regulatory compliance, barcoding and traceability. Our clients fully benefit from DaklaPack’s experience and packaging know-how. By working closely with our experts, all these challenging aspects are balanced.

We understand the importance of product labeling and barcoding, as well as the necessity of robust, comprehensive traceability. DaklaPack spent years developing various advanced techniques to maintain full control over barcoding and the traceability of self-sampling kits. With smart IT infrastructure solutions, we can generate and process large volumes of unique barcodes per kit efficiently.

We have spent years building and refining a software platform that allows you to have full visibility of your products, order data, and sales. Our team of developers is consistently looking at ways to support you with integration to our order API. The DaklaPack team is active in guiding you and building custom features to meet all your needs.

Our customer portal also allows our customers to retrieve data on an individual kit level. With this, you can track which kit each user received, including all related details such as tube barcode, registration barcode, kit ID, outbound and inbound tracking number, lot numbers and, if applicable, the expiration date. This solution ensures seamless information exchange.

There is no one-size fits all solution, each project has its own distinctive requirements. Our packaging background and experience provides us with extensive knowledge of various material options and possibilities for each component. We have direct access to a portfolio of material and design options, which we make available at your fingertips.

DaklaPack produces flexible plastic packaging in-house. In addition, our procurement team has a broad network of manufacturers globally, ensuring access to the right material, products and items for each specific kit. Depending on the kit’s specifications and your preferences, we can place emphasis on high-end luxury kits, eco-friendly recyclable kits with a minimal carbon footprint, easy to use at-home kits and specimen collection kits for professional use.

Prior to kit assembly, our production team gets trained on the specific features of your kit(s) and our software is configured accordingly. Depending on the project we either continuously build kits or work in predefined batches. Batch size is determined in consultation with our clients to ensure the right number of kits is held on stock at all times. During the assembly process, multiple manual and automated checks are set into motion to guarantee no errors are made and that each and every kit exceeds quality standards.

After assembly and passing QC-inspection, the kits are shipped to our client in bulk or transported to our temperature-controlled warehouses for further order processing and fulfillment. For many DaklaPack customers, we provide the last step in getting kits delivered to the user, namely order picking and fulfillment. Orders are sent to us via the order API, and then are processed for fulfillment. We support shipments of individual kits, bulk shipments by case with a combination of kits, by the pallet, and even full truckload deliveries, catering to your every need.

Why choose us as your kitting partner?

When outsourcing medical kits, trust is essential. You need a partner who thinks ahead, works with precision and leads the way in quality and logistics. DaklaPack offers that assurance, with well-structured processes and a team specialized in medical kitting and fulfillment. With our own kitting facilities in the Netherlands and the United States, we can support you worldwide. These are the advantages of choosing DaklaPack:

- One point of contact from kit to result

- Full traceability at kit and component level

- Certifiable quality and secure data handling

- Team with expertise in healthcare, logistics and analysis

- Flexible scalability and professional customization

Frequently Asked Questions

Entrust your kitting needs to DaklaPack

DaklaPack has been a specialist in medical kitting for many years and has a proven track record of working successfully with a wide range of clients in healthcare, government and business. From design to fulfillment, including analysis, returns processing and system integration. Want to know what we can do for your organization? Contact us for a no-obligation proposal.